Produced water souring is common in regions such as the Permian, where the water often contains sulfates. Sulfates are the building blocks of H2S pit souring. Sulfide forming bacteria (called SRB) thrive in a produced water environment because it has salts (nutrients), hydrocarbons (carbon/food source), particulates (growth media), and warm temperatures (incubation). It only takes a matter of weeks for these bacteria to be in full bloom and sour a produced water pit with H2S, which presents numerous health and safety issues.

The SRB also wreak havoc below ground- they thrive downhole and can wreck a well’s production. They have been incubated in the very medium that stimulates conditions downhole. Re-using water without addressing SRB controls is asking for trouble! That water will inoculate and sour what could otherwise be a sweet well. So what to do?

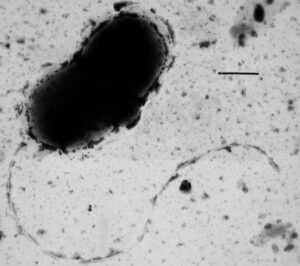

The biology of these bacteria is as interesting, as it is undesirable. Almost all life consumes oxygen to survive, but how it gets that oxygen can vary. Mammals breathe oxygen from the air. Fish “breathe” dissolved oxygen in water using their gills. SRB do it differently. They pluck their oxygen that is molecularly bound in other forms; in this case, the oxygen source is in the form of sulfate, which is SO4-2. Basically, H2S is a byproduct of the SRB respiration. By removing the oxygen, the leftover sulfur atom is converted to the H2S byproduct. SRBs have a competitive advantage downhole, where there is no free oxygen available. A similar advantage exists at the bottom of a stagnant pit, where there dissolved oxygen contents are very low. Most SRB are anaerobic, meaning free oxygen will often kill them outright.

Knowing the biology now, means we know a way to fight it- with oxygen!

One low-cost method to controlling SRB in a pit is to add dissolved oxygen. The trick is to add the dissolved oxygen to the bottom of the pit, where the SRB are most prevalent. Simply drop submerged aeration diffusers in the bottom of the pit and feed them with an air compressor. The power consumption for a small compressor system is generally low enough to run off of household-level electricity. Fine air bubbles dissolve oxygen into water sending the remaining nitrogen to the surface. This raising motion of the bubbles effectively mixes the pit. Moving bottom water to the top kills additional SRB with surface air oxygen contact. In turn, moving surface water to the bottom brings more oxygen below, and you guessed it, kills more SRB. The aeration process also cools the water in the pit or pond, which decreases evaporative losses. Water evaporation is a major concern for regions like the Permian, where water is already a scarce commodity.

The aeration process also cools the water in the pit or pond, which decreases evaporative losses. Water evaporation is a major concern for regions like the Permian, where water is already a scarce commodity.

Select provides this service and is currently installing 7 such aeration systems into produced water ponds for one major operator in the Permian region this July and August. For more information on aeration or water quality monitoring, contact an expert!